Download: Infrared emitter spec sheet

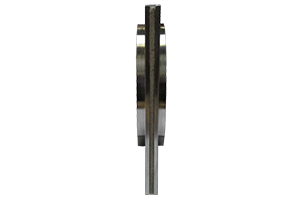

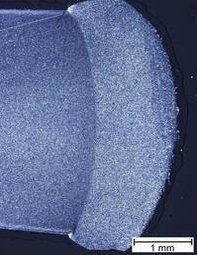

Bilateral beaming infrared emitter

New contour-tracking infrared emitter with a high energy efficiency. There are several advantages:

– low weight (low mass inertia, low acceleration forces of the machine necessary)

– low thermal inertia (sensitive responding behaviour and an precise control)

– little installation space / slimline design

– no smoke formation when heating carbon-black filled plastics

– short changeover time

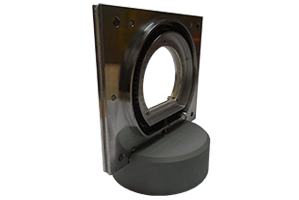

Heating phase PEEK-tubes:

– low mass

– robust construction

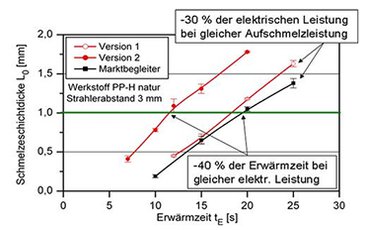

– medium-waved emission spectrumComparative weld tests:

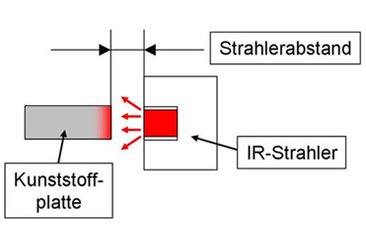

Experimental setup:

Horizontal warm up of sheets with 4mm thickness

Emitter distance: 3 mm |  |  |

| The new IR-emitter: | The competitor: | |

| Symmetric profile | Titled profile because of the convenction between emitter and component surface |

With the new developed emitter in the short- and medium waved radiation spectrum there are a number of technological advantages. The construction of the emitter enables the bilateral radiation yield. The emitter only needs a very little installation space and his tare weight is very low in comparison to other emitters. This, in turn, gives benefits in terms of the dynamic and the availability of the system.