Overview of our welding machines for joining plastics

About welding plastics

Plastic welding as a process is not only more environmentally friendly than gluing plastics, but also more economical. There is no need for an additive. The special challenge in the development of equipment, processing devices and plastic welding machines for the most diverse areas and industries are, on the one hand, the materials, their required processing or welding processes and their implementation in the respective required concept. This applies to small hand-held devices as well as to jigs and fixtures, special machines and even large-scale plants and complex machine systems.

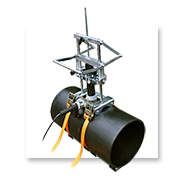

If various mechanical or thermal loads occur on or in components, plastic welding is the safest or sometimes even the only way to join parts together. In pipeline construction, for example, this process allows pressure loads of up to 10 bar and more, and thermally stressed components in the engine compartment of cars and trucks are no longer a problem. Plastic pipes that are welded together are also frequently found in the area of supply line systems. We offer you competent advice and implementation for all types of machines and systems you need for plastics processing. To illustrate the diversity of plastic welding, you will find the most important plastic welding processes below.

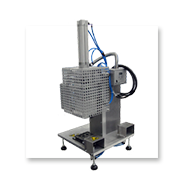

Hot plate welding

Butt welding, swing-bend welding, socket welding with the respective heating element. By means of a heating element, two plastic parts are heated and then joined together.

Friction welding

Heating takes place through mechanical friction. It is usually generated by a movement between a rotating and a stationary joining part, which are then brought together under force.

Radiation welding

Non-contact welding by using radiation sources in different wavelength ranges. High temperatures are achieved. Infrared welding is a contactless welding process. Due to the possible high heating temperatures of the components, the process is particularly suitable for high-performance plastics. Temperatures of up to 600° are possible without any problems.