GR-BSM 1200 – 4500

The innovative large pipe sawing system for plastic pipes

Currently, most water, sewage and rainwater transport systems consist of plastic pipes with a diameter of up to 4.5 m. Processing pipes with such large diameters requires exceptional precision and compliance with safety regulations.

RIEXINGER large pipe saws are designed to meet the requirements of modern production. Almost the entire cutting cycle is computer-controlled, and employee involvement is limited to monitoring the working machine.

All benefits at a glance

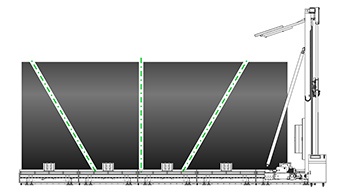

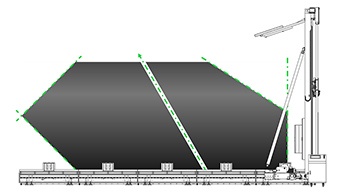

- Innovative design with movable saw bow and open working area

- Automatic cutting of segments without moving the pipe

- The low-positioned working platform makes loading and unloading considerably easier

- Easy replacement of the saw blade without a lift or ladder

- Precise adjustment of the cutting position without having to move the pipe

- Precise cutting at various angles

A new standard in the large-diameter plastic pipe sector

Compared to conventional solutions for sawing large diameter pipes, the use of Riexinger saws results in time savings of up to 50-60%. The sawing is characterised by a precise finish of the machined planes, which require no further machining and guarantee a perfect fit of individual elements. Thanks to the possibility of using different types of saw bands, Riexinger saws can perfectly process any type of material with a wall thickness from a few mm to over 140 mm.

All large pipe saws are equipped with effective safety devices as standard:

- Emergency switch,

- Overload modules for drives and electronic components,

- electronic brake of the saw band,

- Laser projection of the cutting line etc.

Each saw is operated via a large control panel with touch screen. The operator sets the parameters for the subsequent cutting steps step by step by selecting the corresponding symbols.

Saw blade change: simple, safe and fast

RIEXINGER sets new standards in the field of saw blade replacement, both in terms of safety and operating time. Normally, replacing the saw bands in a large saw is a time-consuming and complicated process that requires additional ladders and suitable tools. With Riexinger saws, the arm can be lowered without any problem, without the need for an external crane or lift.

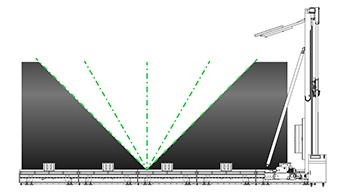

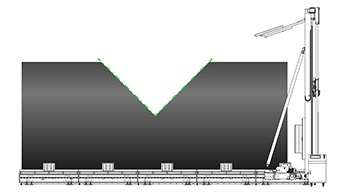

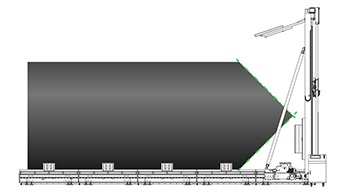

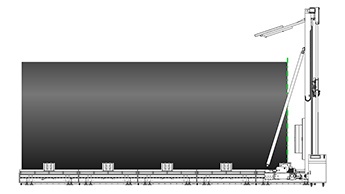

Perform almost any cut

With the help of this sawing system, any required cut can be produced cost-efficiently. A variety of contour cuts are possible without having to move or rotate the tube. This results in a previously unattainable accuracy and quality as well as an enormous time saving.

Standard cuts which are included in the scope of delivery of every large pipe saw

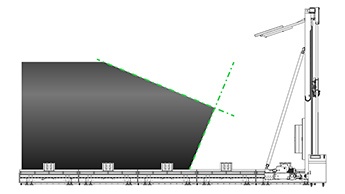

Infinitely adjustable angle cut in the range from 45° to 135

V-cut on the main pipe to create T-pieces

V-cut at the outlet pipe for the production of T-pieces

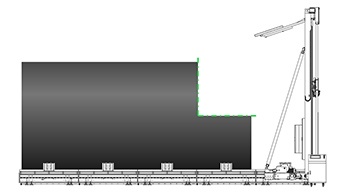

90° straight cut for cutting pipes to length or for pipe end machining

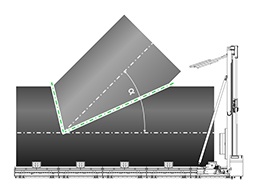

67.5°/22.5° cut on the outlet pipe to create Y-pieces

90° cross section

Even more flexibility with additional optional cutting options

Creation of flexible Y-pieces with variable angle in main and outlet pipe

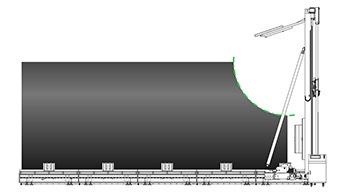

Radius cuts on the outlet pipe

Programmable cutting sequences that can be stored as so-called recipes

Individually configurable cutting sequences for every application

Experience the GR-BSM 3500 large pipe saw in action

Technical data

Dimensions and weight

| GR-BSM 1200 | GR-BSM 2500 | GR-BSM 3500 | GR-BSM 4500 | |

|---|---|---|---|---|

| Length: | 8,400 mm | 8,400 mm | 10,600 mm | 12,600 mm |

| Width: | 5,000 mm | 6,600 mm | 7,800 mm | 8,900 mm |

| Height: | 3,000 mm | 4,300 mm | 5,300 mm | 6,400 mm |

| Weight: | 5,000 kg | 7,000 kg | 9,000 kg | 12,000 kg |

| Sawing range: | 315 – 1,200 mm | 630 – 2,500 mm | 630 – 3,500 mm | 630 – 4,500 mm |

| Further variants and sizes on request. |

Electrical connection

| GR-BSM 1200 | GR-BSM 2500 | GR-BSM 3500 | GR-BSM 4500 | |

|---|---|---|---|---|

| Operating voltage: | 400 V | |||

| Frequency: | 50/60 Hz | |||

| Fuse: | 32 A | |||

| Connected load: | 20 kW | |||

| Connected load main drive: | 5,5 kW width overload protection | |||

Scope of delivery

he following is included in the scope of delivery:

- 1x basic machine “GR-BSM”

- 1x Control panel

- 1x operating manual

- additionally selected options and equipment

We are happy to advise you

You are interested in our product and would like further information? Our contact persons will be happy to advise you in a personal conversation.

Frank Wadle

Sales

T: +49 (0) 7052 930 90-35

M: +49 (0) 151 234567890

E: f.wadle@riex.de